AIM: to assess the uniformity of diameter, thickness and hardness of tablets

DATE: 4th December 2014

INTRODUCTION:

Tablet

is one of the most common dosage form available and it is widely exceptable .

Therefore, we need to ensure that the tablets fulfill the standards found in British

Pharmacopoiea and United Pharmacopoiea for exmple uniformity of

diameter, thickness and hardness. Tablet Hardness Tester is a device that can

measure the mechanical integrity of a tablet including diameter, thickness and

hardness of a tablet. The uniformity of these parameters are very important.

This is because too soft tablets can disintegrate in transport, meanwhile too

hard tablets could damage teeth. An acceptable hardness is required and tablet strength testing is

necessary for both, research & development of new formulations, and for

quality control.

METHODOLOGY:

Apparatus and

materials:

•

Mefenamic

acid 500mg tablets

•

Tablet

Testing Instrument (PHARMATEST PTB 311)

Procedure:

- 10 tablets were selected and tested for

uniformity of diameter, thickness and hardness using Tablet Testing

Instrument (PHARMATEST PTB 311).

- The

results were recorded and the deviation

of individual unit from the mean diameter was calculated. The

deviation should not exceed ± 5%

for tablets with diameter of less than 12.5 and ± 3% for diameter of 12.5

mm or more.

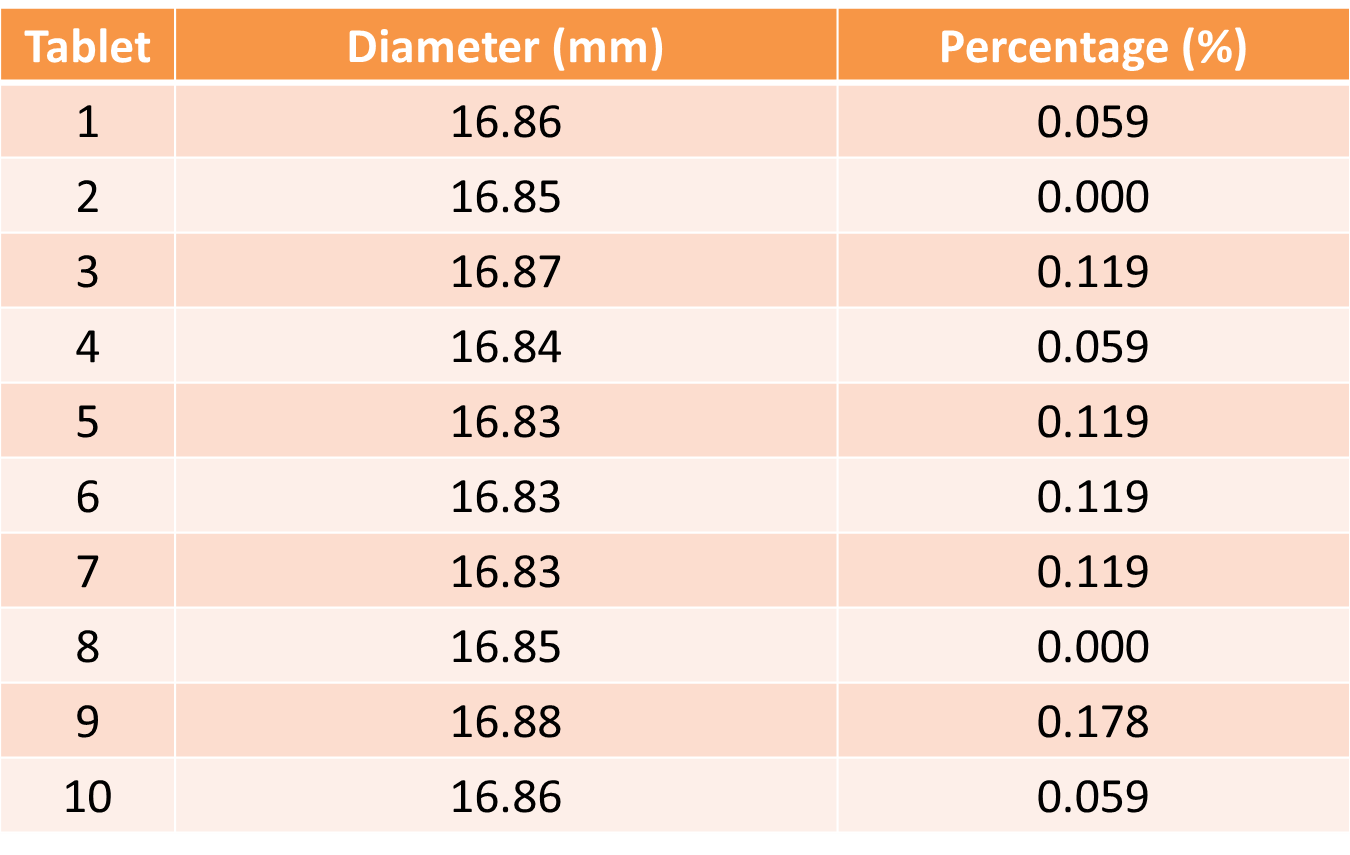

RESULTS AND CALCULATIONS:

CALCULATION:

Mean of diameter (mm) = Total

diameter of all tablets

10

= (16.86 + 16.85 + 16.87 +

16.84 + 16.83 + 16.83 + 16.83 + 16.85 + 16.88 + 16. 86)

10

10

= 16.85 mm

Percentage

(%) = │ (Experimental diameter – Mean diameter) / Mean diameter│ X 100

DISCUSSION:

In

this experiment, 10 tablets of Mefenamic Acid of 500mg were used to test their

uniformity in diameter, thickness and hardness. Based on the results obtained,

it showed that the thickness and diameter of each tablet were uniform in the

range of 0.57-0.69 mm and 16.83-16.88 mm respectively. This indicates that the

tablets have achieved the uniformity in diameters and thickness.

The

uniformity of diameter of the tablets can be further proven with the percentage

difference. Theoretically, tablets with diameter 12.5 mm or more than 12.5 mm

would have not more than 3% of individual deviation from the average diameter.

From the results obtained, all tablets have percentage deviation below 3%. This

shows that each tablets obeyed the

theoretical value of standard diameter.

Next,

for the hardness of tablets, the result proved that each tablet have its own

hardness. There were three tablets that showed relatively strong hardness which

are tablet 1 (146.6) , tablet 5 (152.1) and tablet 8 (153.5). The tablets must

be hard enough to withstand mechanical stress during packaging, shipment, and

handling by the consumer.

CONCLUSION:

In

pharmaceutical formulation, tablets of the same type have a uniform value in

their diameter and thickness. However, the hardness of the tablets in this

experiment varies. The range of the least strength and the strongest tablet is

between 101.5 to 153.5. This shows a big difference and it can be concluded

that the hardness were not uniform.

REFERENCES:

Dr. Mukesh Gohel. Pharmaceutical Tablets Advantages and Disadvantages. http://www.pharmainfo.net/tablet-ruling-dosage- form-years/what-tablet [ 6 Disember 2014]

Schleuniger. Tablet Hardness

Test. http://www.pharmatron.com/products/hardness- testers/ [6 Disember 2014]

The Pharmaceutics and Compounding Laboratory. http://pharmlabs.unc.edu/labs/tablets/evaluation.htm [6 Disember 2014]

No comments:

Post a Comment